Industrial technology of charging piles

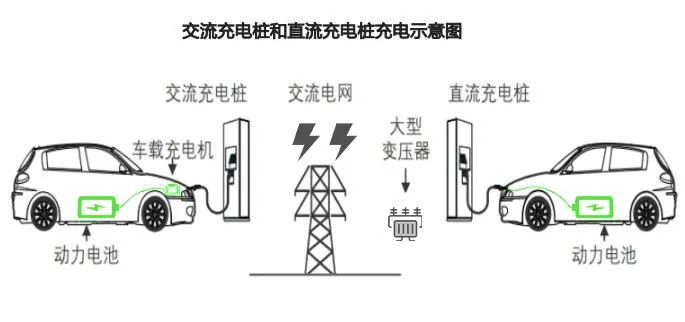

According to different current output modes, charging piles can be divided into AC charging piles and DC charging piles. Both are fixed outside the electric vehicle and connected to the AC power grid. The main difference lies in the AC-DC converter link. The AC power directly output by the AC charging pile needs to be converted into DC power by the OBC in the car before being charged to the battery. The charging speed is slow, commonly known as "slow charging", while the DC charging pile has an external AC-DC converter link, and the output DC power It can charge the battery directly, and can achieve great charging power through parallel connection of multiple modules. The charging speed is fast, commonly known as "fast charging".

1. AC charging pile

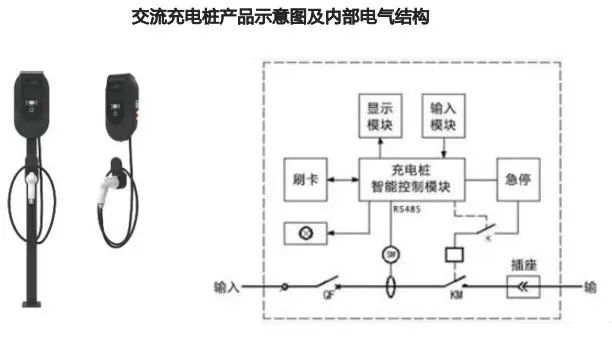

There is no charging module, it only provides power output and needs to be connected to a car charger.

The AC chrging pile needs to be connected to the on-board charger in the car to directly convert the AC input (220V/380V) into a high-voltage DC output for charging the electric vehicle. It only serves to control the power supply.

Internal electrical structure of AC charging pile: The electrical part of AC charging pile consists of main circuit and secondary circuit. As shown in the figure below, the main circuit is composed of input protection circuit breaker, AC smart energy meter, AC control contactor and charging interface connector; the secondary circuit is composed of control relay, emergency stop button, operating status indicator light, charging pile intelligent controller and It consists of human-computer interaction equipment (display, input, card swiping).

AC charging pile power: AC charging piles have smaller power and slower charging. They can be divided into single-phase (mainly 7kW) and three-phase (mainly 40kW). Due to the power limitation of the on-board charger, the power is generally small and charging is slow. The main powers are 3.5kW, 7kW, 11kW, 21kW, 40kW, etc. In the current domestic AC charging pile market, the single-phase is mainly 7kW, and the three-phase is 40kW. host.

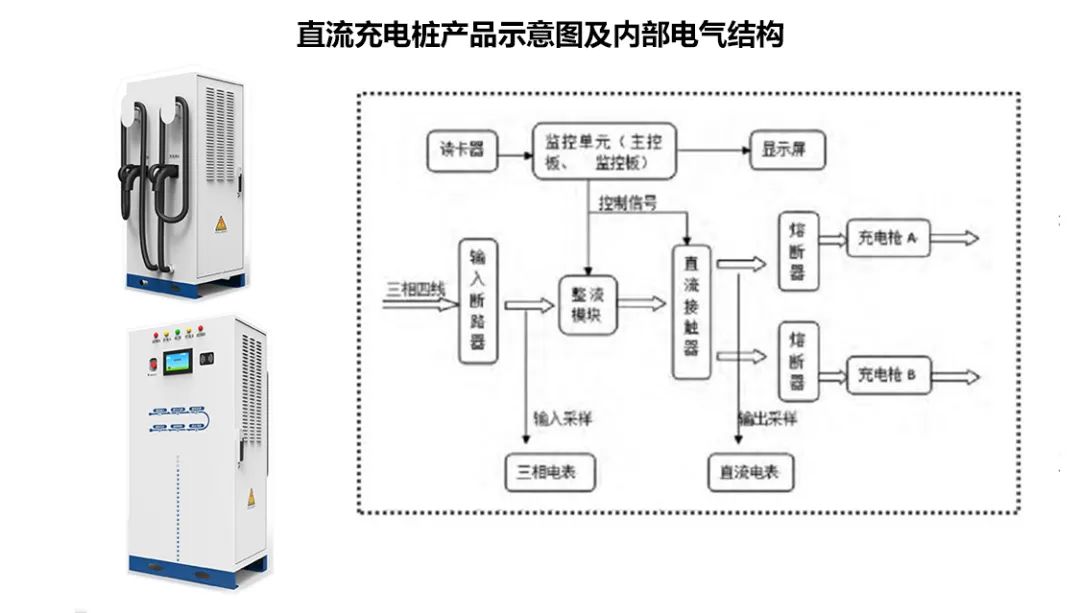

2. DC charging pile

The DC charging pile converts AC into DC output and directly charges the battery. It has high power and fast charging speed.

Basic composition: DC charging pile consists of power unit, control unit, metering unit, charging interface, power supply interface and human-computer interaction interface. The power unit refers to the DC charging module, and the control unit refers to the charging pile controller. These two components form the core of the technology. In addition, the structural design is also one of the key points in the reliability design of the entire pile.

Internal electrical structure of DC charging pile: The electrical part of DC charging pile consists of main circuit and secondary circuit. The main circuit is that the three-phase AC power passes through the input circuit breaker and the AC smart energy meter, and then the charging module (rectifier module) converts the three-phase AC power into DC power that the battery can accept, and then connects the fuse and charging gun to charge the electric vehicle. The secondary circuit is composed of a charging pile controller, a card reader, a display screen, a DC meter, etc.

DC charging pile power: Modular combined power is used. A single charging module has 15kW, 20kW, 30kW, 40kW and other powers. Therefore, the output power of DC charging piles is generally 30kW, 60kW, 120kW, 240kW, 360kW, 480kW, etc. A charging pile is usually composed of multiple charging modules connected in parallel. For example, a 120kW charging pile can be composed of 8 15kW charging modules or 4 30kW charging modules.

At present, high-power DC charging technology has received widespread international attention. Countries have successively carried out research and standard formulation of high-power charging technology. The maximum power of Japanese standard CHAdeMO and national standard GB/T DC fast charging is moving from 400kW/250kW to 900kW. Europe has completed It has established a 350kW high-power charging standard system and is currently developing towards 460kW together with the American Standard.

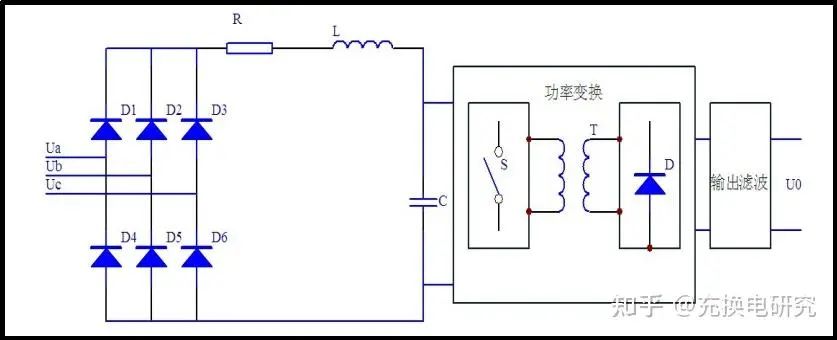

3 How the charging pile works

The general structural block diagram of pure electric vehicle charging is shown in the figure below. The working principle is: AC power is input from the three-phase power grid, converted into DC power through the bridge uncontrollable rectifier circuit, filtered by the LCR circuit and sent to the high-frequency DC-DC power converter. The power converter outputs the required DC voltage through DC-DC conversion. , after output filtering, it charges the electric vehicle battery.There are four charging modes available: fixed quantity, fixed time, fixed amount, and automatic (until full).

The automobile industry faces an important period of development opportunities

Since the beginning of this year, the automobile market has continued to perform well. At this···

China Automobile Synergy Zongqi: Charging infrastructure should show differentiated development

The 2023 China Automobile Charging and Swapping Ecosystem Conference was held in Hangzhou. Ton···

Xinjiang charging pile access monitoring module creates information security

State Grid Xinjiang Information and Communications Corporation recently completed the charging···

Zhejiang Development and Reform Commission: Standardizing electricity prices for electric vehicle charging and swapping facilities is expected to drop by 10%-15%

Recently, the Zhejiang Provincial Development and Reform Commission and the Provincial Market Superv···

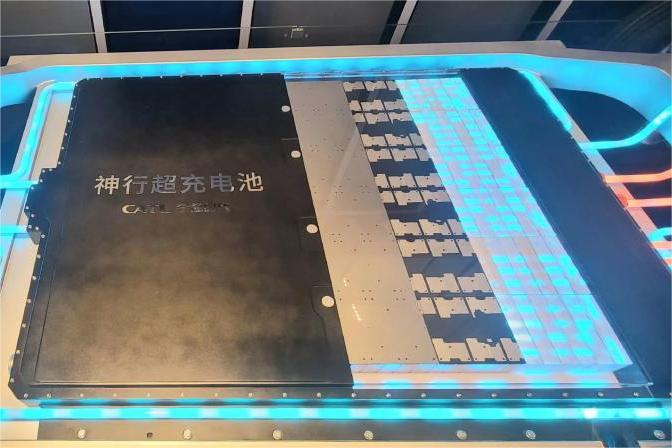

Shenxing superchargeable battery wins award, new choice for 750 million European consumers

Looking around the world, since 2023, battery companies have been competing with each other, and ult···

Super fast charging “makes charging as fast as refueling”

In recent years, the state has successively introduced favorable policies for the construction of su···